Gcodes and Mfunctions Milling Drilling Machining

From my experience, I can say that easily most of the codes are the same, but some manufacturers have special M-codes and G-codes. For example, some of the codes I found very helpful; G05.1 Q1: I used this code on Fanuc Milling controller-OM to activate highspeed machining mode with high precision mode. Machined parts are more precise with this.

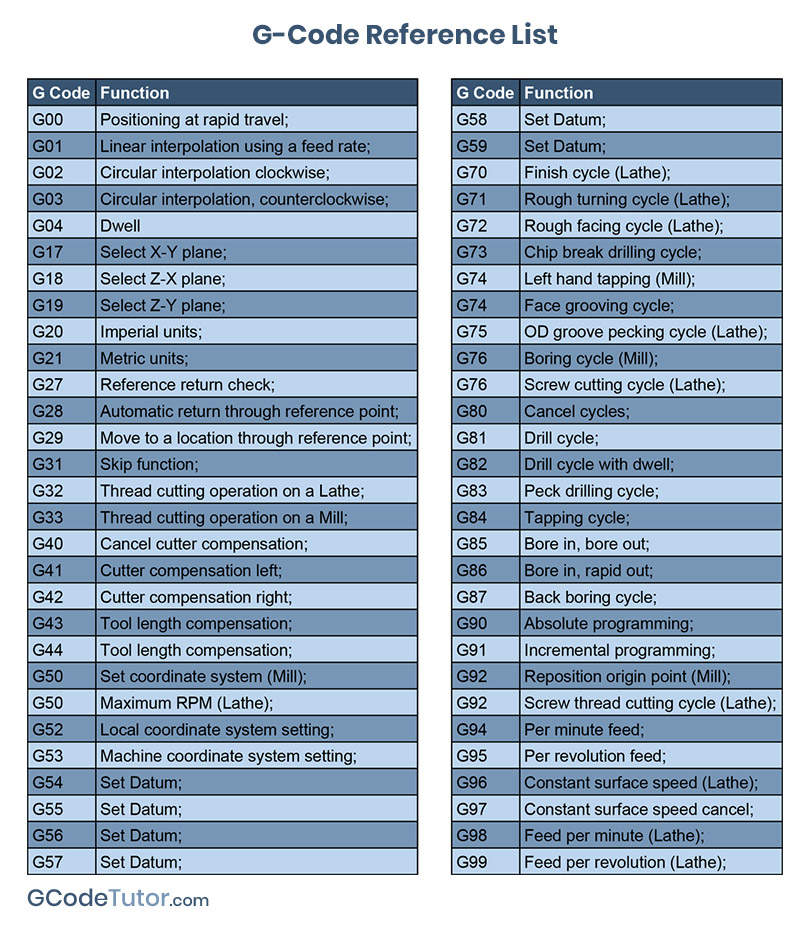

CNC G Codes Learn how to program CNC machines with GCode

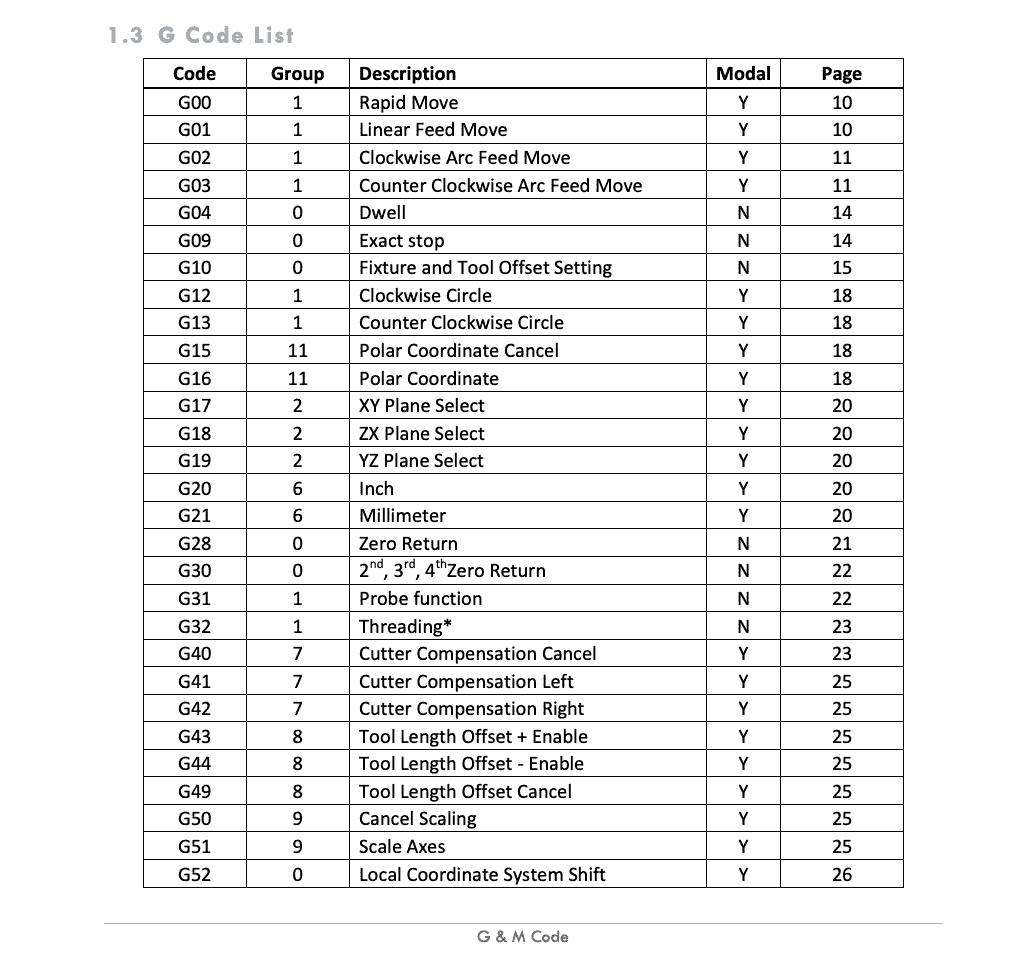

6/30/15 R0135 This manual covers the G and M-codes used in Mach4 Lathe. Formatting Overview: • Menus, options, icons, fields, and text boxes on the screen will be bold (e.g. the Help icon). • Clickable buttons will be bold and within brackets (e. g. the [OK] button).

Introduction About G Code and M Code In CNC Manufacturing SANS

M08 - Coolant On. The M08 code is a command used in CNC machines. It tells the machine to turn on the cooling system. This cooling system helps stop the machine and its tools from getting too hot. The M09 code, on the other hand, tells the machine to turn the cooling system off.

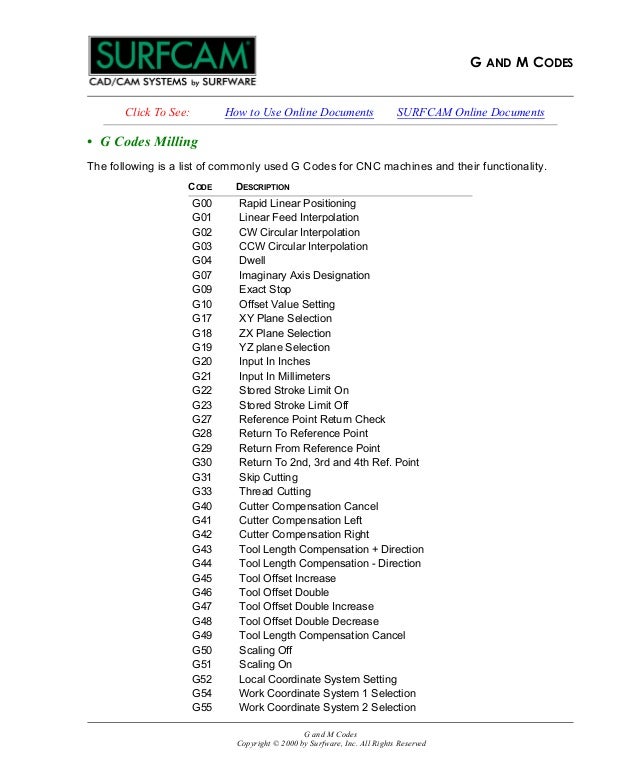

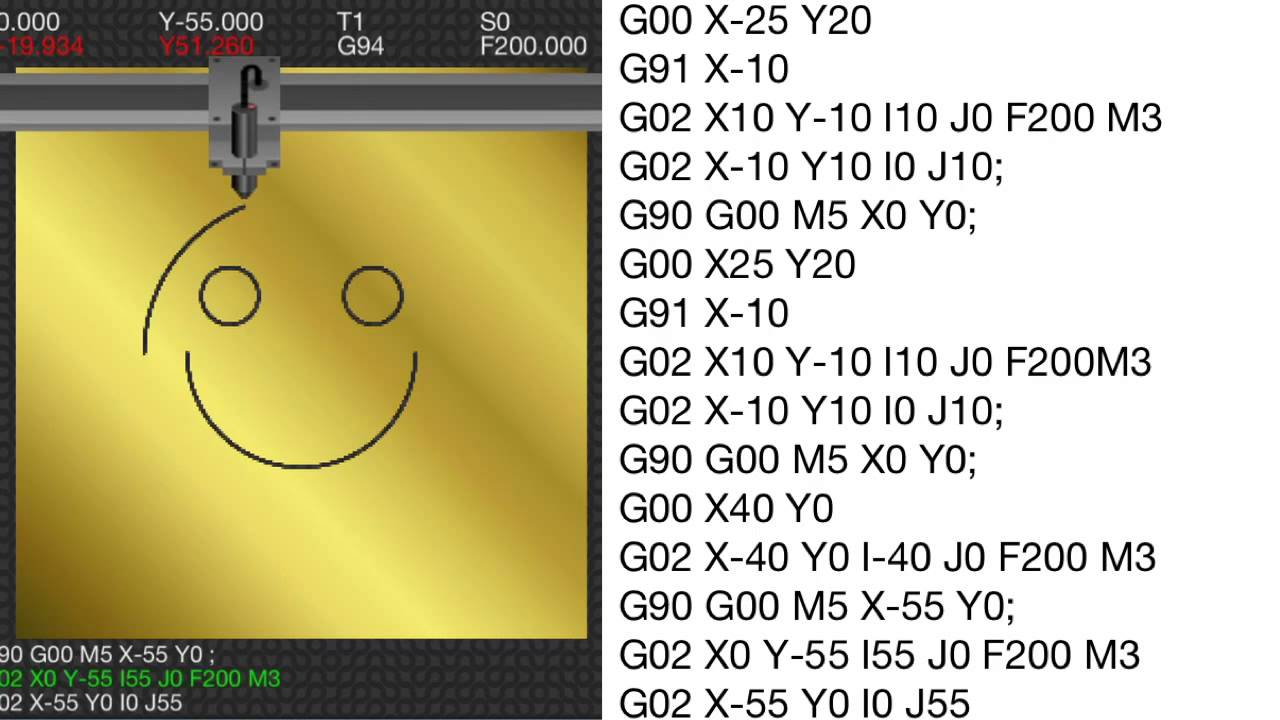

CNC MILLING GCODE MCODE SOLO CAD DESIGNER

G code (also RS-274D) is the most popular CNC programming language. Most G code commands are in alphanumeric format and start with G which stands for geometry. They are responsible for the movements of CNC machines, telling the machine where to start, how to move, and when to stop when fabricating a part.

GCode and MCode List for CNC [ Easy To Use, Examples & Tutorials ]

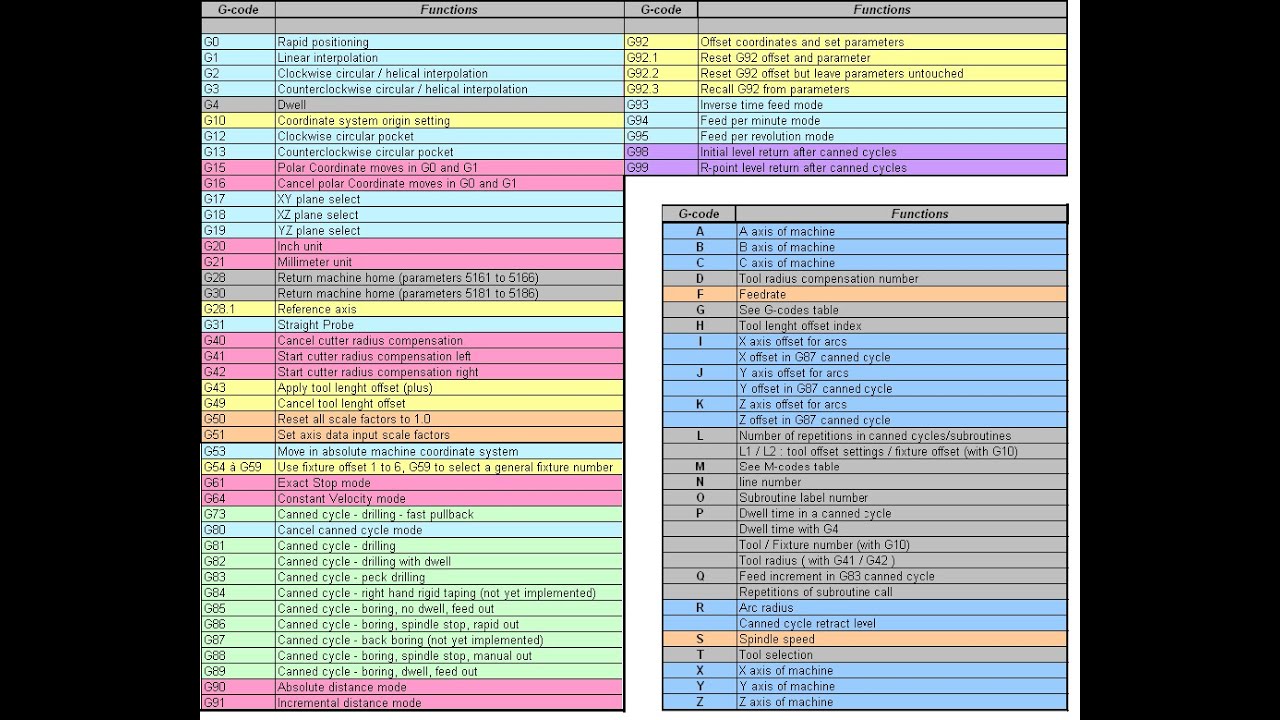

G03. Motion. Counter-clockwise circular arc at (F)eedrate. XYZ by end-points IJK relative to center R for radius. G04. Motion. Dwell: Stop for adenine particular time. P for millions X for seconds.

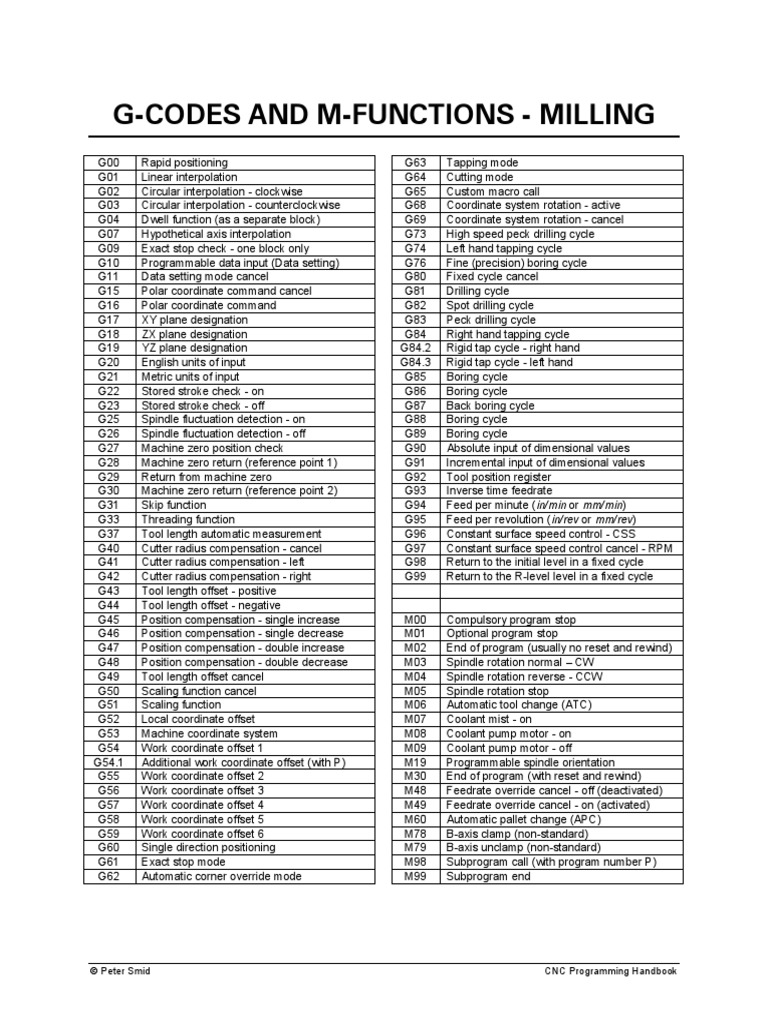

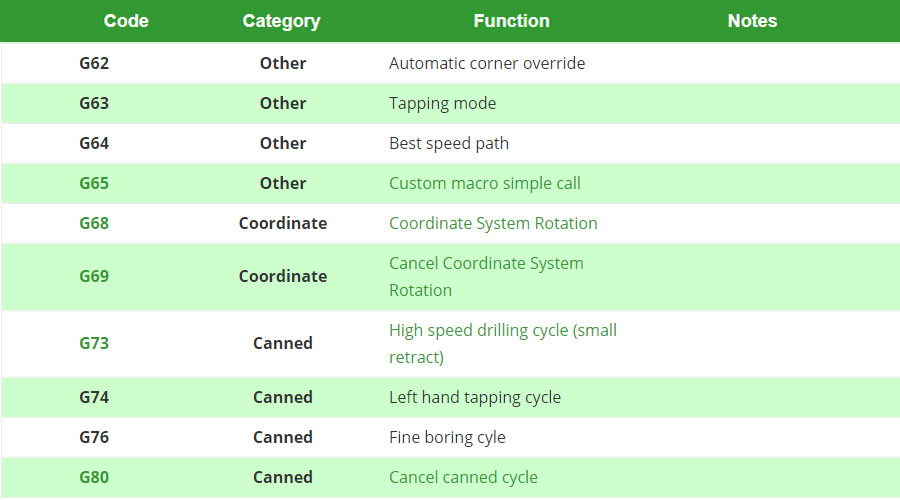

G and m codes

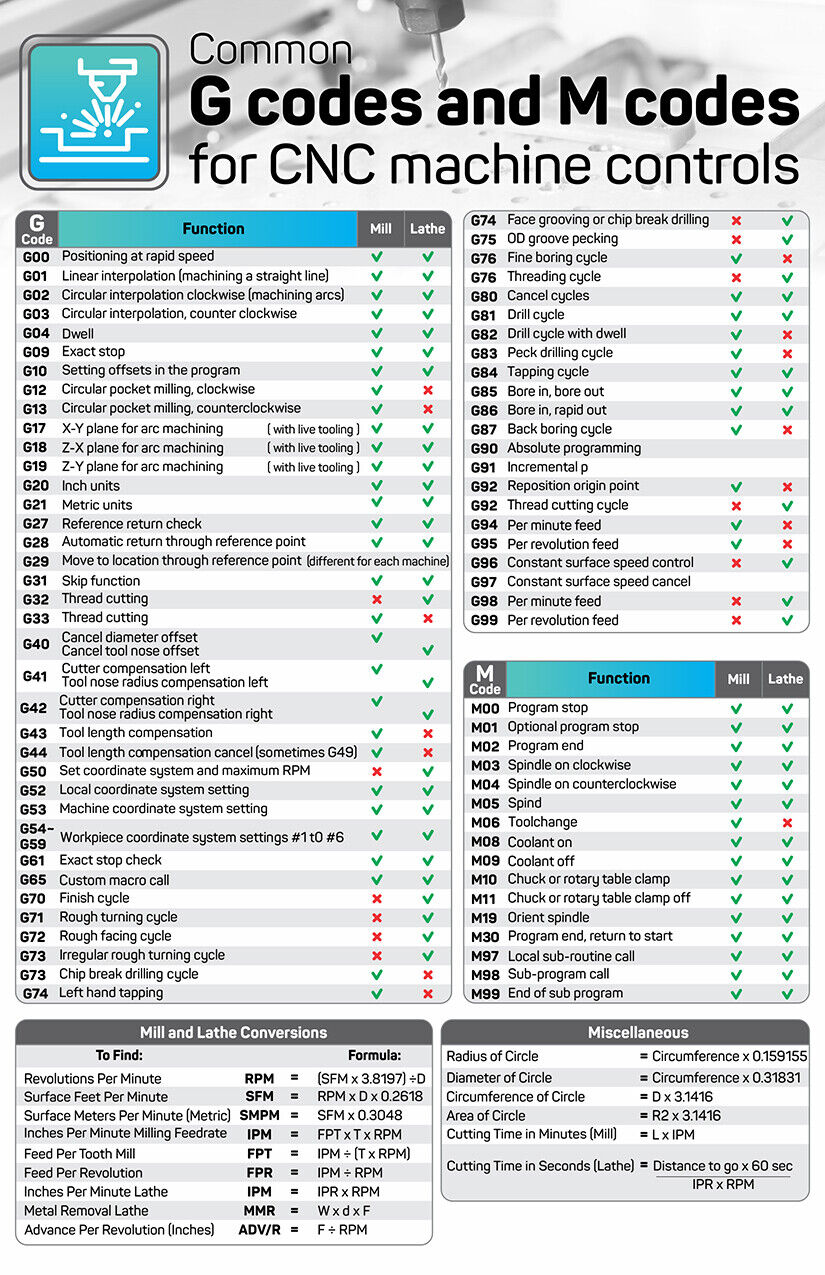

This Downloadable PDF contains two lists of G-codes and M-codes for both Machining centers and lathes for most machine builders. Download consists of one G and M code cheat sheet on a 8.5 X 11 page with all the basic information you may need to modify most programs on most machines on the spot.

G Code List PDF Download

Sherline CNC Machine Shop Packages For a list of the G and M-codes used on our Accu-Pro machines with the MASSO control, go to the MASSO G and M-Codes page. Common G-Codes g00 rapid positioning g01 positioning at a given feed rate g02 circular/helical interpolation (clockwise) g03 circular/helical interpolation (counterclockwise)

CNC Machining G Code and MCode

G-code is a programming language for CNC (Computer Numerical Control) machines. G-code stands for "Geometric Code". We use this language to tell a machine what to do or how to do something. The G-code commands instruct the machine where to move, how fast to move and what path to follow.

Understanding G and M Codes for CNC Machining RapidDirect

49 M Code/G Code List Below you will find a list of common codes many builders use. Please remember, all machines may be configured differently and the list below may not match your machine perfectly. If fact, virtually all M-Codes above M79 will vary from builder to builder. Please make sure to contact your machine tool builder to be sure.

CNC Turning (FANUC) GCode MCode SOLO CAD DESIGNER

G code can be used to realize rapid positioning, inverse circle interpolation, along circle interpolation, middle point arc interpolation, radius programming and jump processing. What is M-code? M code is defined as auxiliary function code in FANUC program.

Introduction About G Code and M Code In CNC Manufacturing SANS

G-code is developed from APT programming language which contained data about cutter (tool) location or geometry, and other non-geometry machine functions such as spindle speed, cooling, etc. RS-274 functions (G and M codes) inherit the basics from APT programming language with minor modifications that have made programs shorter and more convenie.

Common GCodes & MCodes for CNC Machines Chart 5.5"x8.5" eBay

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.

Master List of CNC G and M Codes Drilling Machining

The list of M-codes begins with M00 (program stop) and continues up to M99 (subprogram end), although every number is not assigned. The following is a partial list of M-codes: M00 Program stop; M01 Program stop-optional; M02 End of program; M03 Spindle start-forward, of clockwise rotation;

CNC M Code (1 of 2 CNC G & M codes infographics.). Geek Tech Technology Electronics

M Codes G codes: Full list (Milling & Turning) What is a G code? G-code is the common name for the most widely used CNC programming language. It was developed in the 1950s at MIT. The language is very "primitive" by today's standards. All the commands are represented by codes (G01, G02, etc..) and not by meaningful words.

How to a GCode master with a complete list of GCodes Robotics & Automation News

Fanuc Alarm Code List Complete g code list with m-codes for milling in the Fanuc, LinuxCNC, GRBL, and Haas dialects. We give a quick definition for all g code commands along with a link to tutorials and examples of how to use it.

G Code M Code Reference Chart YouTube

In a typical CNC program, G-codes and M-codes are used in combination. M-code controls the machine functions like the spindle on/off, tool change, coolant on/off, etc. Following are some of the M-codes associated with programming CNC mills. M-Code Function; M00: Compulsory program stop: M01: